Redefining the future of manufacturing: The transformative power of edge computing

Edge computing is transforming the manufacturing industry by enabling real-time data processing and decision-making at the edge of the network.

In today’s hyper-connected and rapidly evolving industrial landscape, manufacturers are under mounting pressure to deliver more than just quality products. They must optimise operations, reduce downtime, embrace sustainability, and innovate continuously—all whilst keeping pace with global competition and technological advancements. The traditional, centralised approaches to managing data and processes are no longer sufficient to meet these demands. Enter edge computing, a disruptive technology that brings real-time data processing and decision-making closer to where the data is generated. As the manufacturing industry stands on the brink of a new era, edge computing is emerging as a critical enabler for transforming factory floors, enhancing efficiency, and fostering innovation. But how exactly is this technology shaping the future of manufacturing, and what challenges does it address? Let's explore the journey to the edge, where smarter, safer, and more sustainable manufacturing is becoming a reality.

The rise of edge computing: A catalyst for change

The shift of enterprise workloads to the cloud has been ongoing for years, but it has also highlighted the limitations of centralised data processing, especially in industries where milliseconds can impact outcomes. Edge computing offers this solution by pushing processing power closer to where data is generated such as sensors, machines, or factory equipment. Instead of sending all the data to a distant centralised cloud for processing, edge computing allows data to be processed locally—at the "edge" of the network. By doing so, it enables low-latency data processing that traditional cloud infrastructures cannot match. According to Gartner, by 2025, 75% of enterprise data will be processed at the edge.

This is especially important for the manufacturing industry because manufacturing operations often rely on split-second decisions—whether it’s detecting a defect on a production line or preventing machinery from overheating. By processing data locally, edge computing reduces delays and allows for real-time insights and decision-making, which are crucial to maintaining efficiency and minimising costly downtimes.

How is edge computing defining the new age manufacturing industry

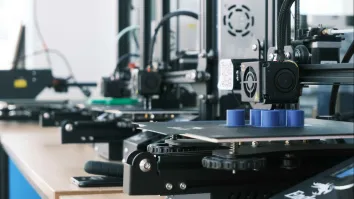

The traditional image of manufacturing—a labour-intensive, slow-moving industry—has undergone a complete transformation thanks to digital technologies. Smart manufacturing is now the buzzword, and edge computing sits at the heart of this revolution. But what does smart manufacturing entail?

At its core, smart manufacturing integrates technologies like automation, IoT (Internet of Things), and data analytics, turning traditional factories into interconnected ecosystems. This shift enables factories to predict equipment failures before they happen, use collaborative robots (cobots) to boost worker efficiency, and enhance safety through real-time monitoring. Here’s how edge computing drives this transformation:

- Innovation and agility: By enabling local data processing, manufacturers can quickly adapt to changes in the market, ensuring continuous innovation across production lines and facilities.

- Quality assurance: Real-time data analysis at the edge allows manufacturers to detect anomalies and make quick adjustments, ensuring high-quality output.

- Operational efficiency: With edge computing, manufacturers can reduce waste, improve productivity, and optimise resource allocation.

As promising as this future sounds, manufacturers still face significant hurdles on their path toward innovation.

Overcoming industry challenges with edge computing

Manufacturers grapple with numerous challenges, many of which stem from the complexity of integrating new technologies into their operations. Some of the most pressing issues include supply chain disruptions, bandwidth limitations, and the high cost of managing vast amounts of data in centralised systems. This requires a shift toward more efficient, decentralised solutions that can process data in real time, optimise resource use, and reduce latency. Edge computing offers precisely that.

By processing data locally, edge computing reduces the reliance on centralised systems and optimises data flow. For example, predictive maintenance powered by edge computing allows manufacturers to anticipate equipment failures before they occur, slashing unplanned downtime and extending the life of machinery. Warehouse automation, another game-changer, utilises Automated Guided Vehicles (AGVs) to manage inventory, fulfil orders, and optimise material handling—all in real time.

These innovations lead to significant cost savings and enhanced efficiency. But the impact of edge computing extends beyond just operations; it plays a pivotal role in addressing sustainability and safety challenges as well.

Edge computing: A game-changer for sustainability and safety

Today’s manufacturers face increased scrutiny over their environmental impact and safety standards. Edge computing offers a solution by providing real-time monitoring and instant decision-making capabilities that help reduce energy consumption, minimise waste, and ensure worker safety.

For instance, edge-powered monitoring systems can instantly detect when a worker enters a restricted area, immediately halting nearby machinery to prevent accidents. This proactive approach not only enhances worker safety but also helps manufacturers comply with ever-evolving regulatory standards. Furthermore, edge computing enables manufacturers to monitor their environmental footprint in real-time, making it easier to adjust operations and reduce emissions. As a result, manufacturers can achieve their sustainability goals whilst maintaining operational excellence, thereby fostering a culture of safety and responsibility throughout their organisations.

The driving forces behind edge computing

The wave of edge computing adoption is being propelled by the convergence of transformative technologies such as Industry 4.0, IoT, AI, and 5G. How are these advancements enabling unprecedented levels of automation, precision, and connectivity in manufacturing? As 5G and Wi-Fi 6 continue to roll out across industries, manufacturers will benefit from faster and more reliable connectivity, significantly reducing their reliance on centralised cloud infrastructure whilst enhancing overall operational efficiency and responsiveness to market demands.

Technologies like AI/ML, computer vision, and robotics are also transforming factory floors, allowing for greater automation and real-time decision-making. By reducing human intervention in repetitive or hazardous tasks, manufacturers can improve safety, boost productivity, and unlock new efficiencies.

As manufacturers harness these technologies to drive innovation and efficiency, Tata Communications’ edge solutions are designed to further enhance these transformative efforts.

Tata Communications CloudLyte: Empowering the future of manufacturing

In response to the evolving needs of enterprises, Tata Communications has developed CloudLyte, a comprehensive and fully automated edge platform. It is thoughtfully designed for seamless integration with all types of cloud environments and is complemented by a suite of fully managed services, making it a user-friendly and efficient solution. Our focus is on helping our manufacturing customers build, secure, and manage enterprise-grade edge applications by prioritising consistency, performance, reliability, and security, all of which are essential for manufacturing edge use cases.

What sets CloudLyte apart is its flexibility. Manufacturers can choose from three deployment options—Prime (SaaS-based), Proximate (edge-in-a-box), and Private (custom edge cloud)—ensuring that they have the right solution for their specific needs. With over 50+ edge use cases spanning warehouse automation, predictive maintenance, and worker safety, Tata Communications CloudLyte emerges as a catalyst for manufacturers embarking on their edge computing journey. It unlocks boundless possibilities at the edge, facilitating smarter factories and enabling business use cases like warehouse automation, predictive maintenance, worker safety, and much more.

The future of manufacturing is at the edge

As investments in edge computing continue to soar, with the market projected to reach $132.11b by 2028, it’s clear that this technology is not just a trend—it’s a game-changer. For manufacturers ready to embrace edge computing, the benefits are clear: streamlined operations, enhanced data security, optimised productivity, and improved sustainability.

The question manufacturers need to ask isn’t whether they should adopt edge computing—it’s how soon can they start. With Tata Communications’ edge solution leading the way, the path to smarter, safer, and more efficient manufacturing is clearer than ever. The future of manufacturing is at the edge, and the possibilities are boundless.

Advertise

Advertise