Indonesia pushes factories past tech ‘pilot trap’

The state wants manufacturers to sustain the digital transformation.

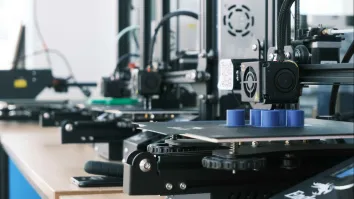

Indonesia is tackling a major obstacle facing manufacturers worldwide: the “pilot trap,” where digital initiatives stall at the trial phase and fail to scale.

Citing a 2019 McKinsey report showing 79% of manufacturers stuck in this phase, Indonesia’s Ministry of Industry has launched the Centre for Indonesia’s Digital Industry 4.0 (PIDI 4.0) to break the pattern through structured support.

“PIDI 4.0 was created to bridge the gap between aspiration and execution,” Masrokhan, head of the ministry’s Industrial Human Resources Development Agency (BPSDMI), told reporters in Jakarta in July. “It’s not just about introducing technology, but ensuring its practical application.”

He said the pilot trap often results from companies adopting technologies without clear implementation plans. “Our role through BPSDMI and PIDI is to ensure that transformation is sustained, adapted, and integrated into operations.”

By the end of 2024, PIDI 4.0 had trained 1,921 workers in digital competencies including Internet of Things (IoT), data science, and smart manufacturing. Ten firms received full transformation planning support, while 338 companies accessed live demonstrations of digital tools to evaluate technologies in real-time production settings.

“We don’t believe in a one-size-fits-all solution,” Masrokhan said. “Each company needs a roadmap that fits its capabilities.”

He said PIDI programs are not limited to large manufacturers in Java. “PIDI’s reach includes small- and medium-scale industries across the archipelago. It’s critical that Industry 4.0 is accessible to all.”

Joji Yamamoto, president-director at NEC Indonesia, said countries like Germany and Japan have overcome the pilot trap through a mature infrastructure and continuous investment in workforce digital readiness.

“From Japan to Europe, we’ve seen that digital transformation succeeds when it’s treated as a continuous process, not a one-time project,” he said in an emailed reply to questions. Indonesia can follow this path with structured, high-impact steps.”

He cited examples from Thailand and Japan, where manufacturers prioritized predictive maintenance, supported by a strong data infrastructure and workforce development. “You don’t need to digitalise everything at once. Start with specific, high-value areas, then scale with confidence, backed by data and expertise.”

Local innovation is also part of the program. PIDI has introduced the Industrial IoT SmartBox, a locally developed tool now used in mid-sized factories to monitor machines in real time. The framework includes the Showcase Centre, Capability Centre, Delivery Centre, artificial intelligence (AI) and Engineering Centre, and a digital collaboration platform.

In the first quarter, manufacturing accounted for 17.5% of Indonesia’s non-oil and gas gross domestic product, employed about 20 million people, and generated $196.54b in exports. The sector received $43b (IDR697.5t) in investment and contributed 26% of national tax revenue.

“Transformation is only possible when human capital is ready and the technology is relevant,” Masrokhan said. “Our mission at BPSDMI is to prepare the people who will lead that transformation—not just in large factories, but in every production line across Indonesia.”

Advertise

Advertise